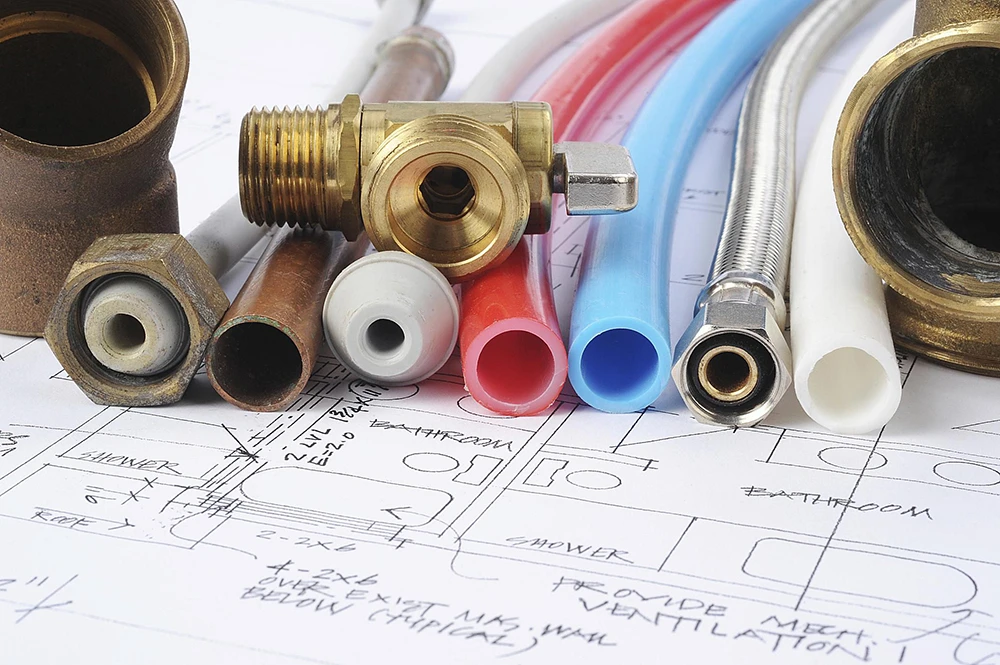

Plumbing- Cast-Iron Pipe Connector Guide

dasfasd

Cut Cast-Iron Pipe

Cutting cast-iron pipe can be a bit challenging, but with the right tools and techniques, it can be done effectively. Here are some methods to cut cast-iron pipe:

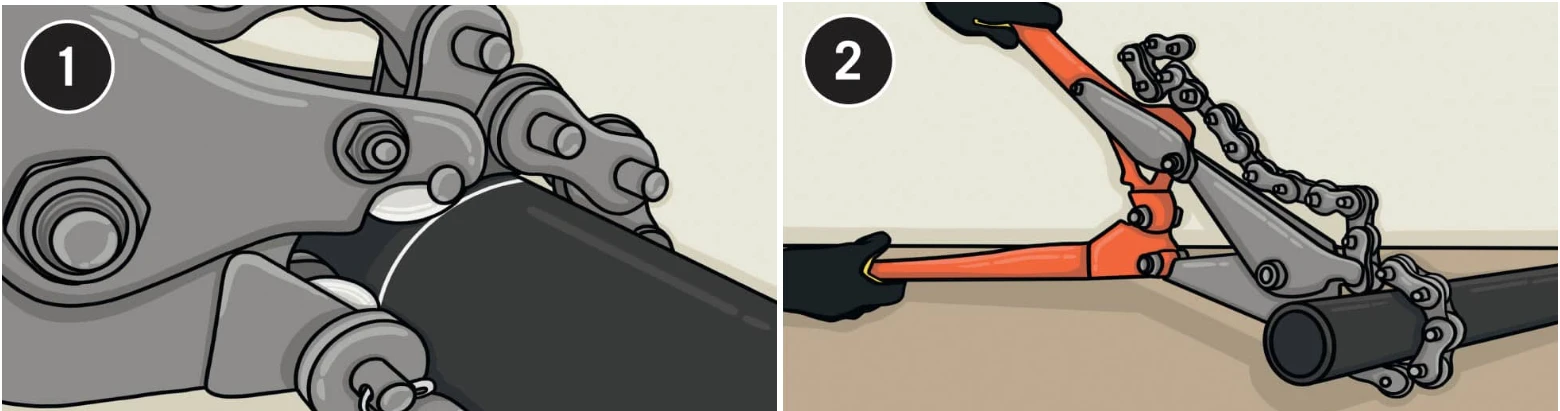

Using a Snap Cutter:

Mark the Pipe: Use chalk to mark the cutting line on the pipe.

Wrap the Snap Cutter: Wrap the chain of the snap cutter around the pipe, ensuring the cutting wheels are evenly positioned.

Apply Pressure: Apply pressure to the handles of the snap cutter to score the pipe. Rotate the cutter slightly and continue applying pressure until the pipe snaps.

Using a Reciprocating Saw:

Using a Reciprocating Saw:

Mark the Pipe: Use chalk to mark the cutting line.

Fit the Saw: Fit your reciprocating saw with a long metal-cutting blade, preferably with carbide or diamond grit.

Cut the Pipe: Hold the pipe firmly and set the saw at low speed. Let the blade do the work, avoiding undue pressure that could cause the blade to snap.

Using an Angle Grinder:

Mark the Pipe: Use chalk to mark the cutting line.

Fit the Grinder: Fit your angle grinder with a metal cutoff blade or a diamond blade.

Cut the Pipe: Slowly lower the grinder blade onto the pipe and cut along the marked line. Be sure to wear proper protective equipment.

Finishing Touches:

Deburr the Edges: After cutting, use a deburring tool or a utility knife to remove any burrs or rough edges from the cut end.

Each method has its own advantages depending on the tools you have available and the specific situation. Always remember to wear appropriate safety gear, such as goggles and gloves, while cutting.

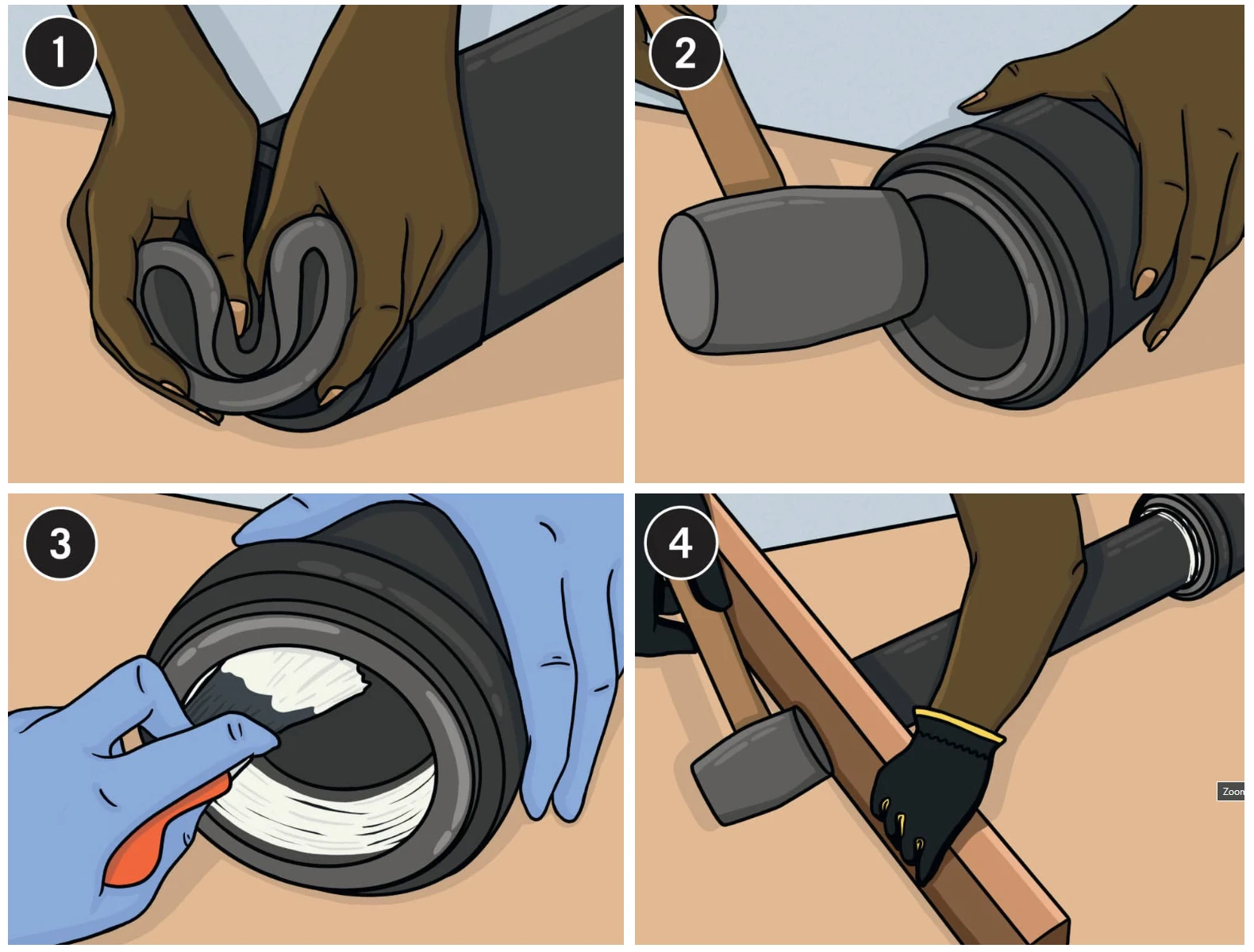

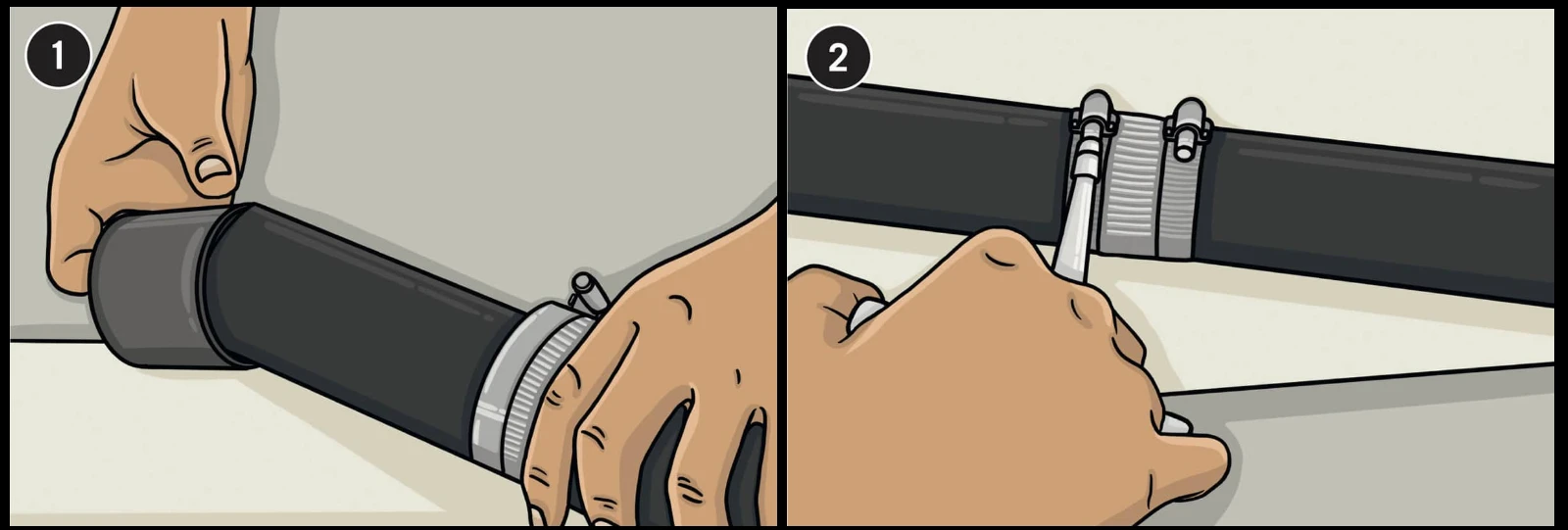

Joint Cast-Iron Pipe :Hubless Coupling

Make sure the ends of both pipes are smooth and clean.Use a coupling that conforms to local codes.Slide the coupling collar onto one pipe end. Insert the pipe end into the coupling gasket until it is securely seated and contracting any inner shoulder.

Hubless Coupling

Silde the other pipe end into the oppsite end of the gasket, seating it securely. Slide the collar over the gasket, so that it is perfectly aligned with the gasket edges on both ends.all around the pipe. Initially tighten the clamp with a 5/16" nut driver. Tighten a little on each side.alternating as you work. Finish tightening the clamp with a 60 inch-pound torque wrench,or whatever torque is required by code.

Hubless Coupling Joint

Hub and Spigot Joint Steps