Tubing Ends tools

Tubing Ends Coning Tools Basic Information

Cut tubing to length and square off the end using hacksaw with at least 32 teeth per inch or abrasive cut-off wheel.

Allow extra length for proper engagement into the connection as listed in design table

Additional 1/16" should be added to each end to compensate for coning/end facing.

Note: When cutting tubing with abrasive cut off wheel, tubing should not be over heated effecting material properties.

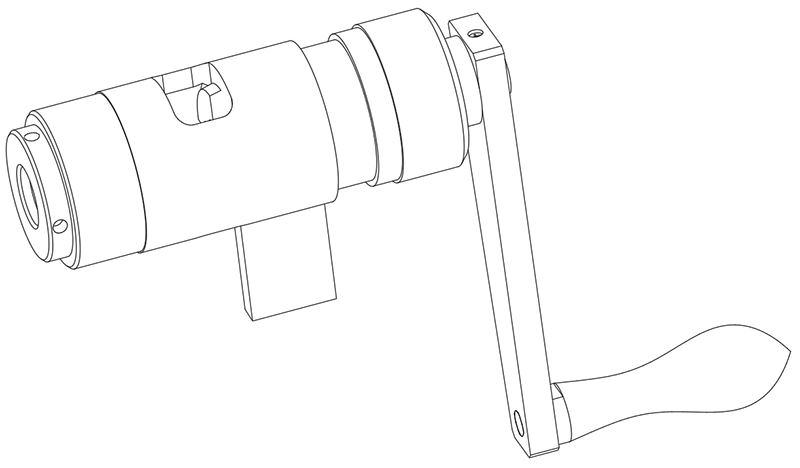

M18X2 UNF Thread Install the collet and collet nut into the bottom of the coning tool housing. Remove the cutter support feed nut from the coning tool housing and install the cutters. This can be done by backing out the four set screws in the cutter support.

Place the coning tool housing (or optional support arm), without the feed nut/cutter support assembly, in a vise. The vise should be equipped with soft jaws, and the housing should be placed in the vise to allow lubricant to flow to the cutters and cone.

Slide the tubing through the collet until the end of the tube appears in the coning tool housing window . Line the end of the tube with the edge of the window as marked above and tighten the collet nut firmly in place using the collet nut wrench.

After tube is coned, threaded and de burred,

check for proper thread fit and length with a new

collar of the proper size.

Note: Remember to flush all tubing prior to

installation with a fluid that is compatible with

the process fluid being used.

Tubing Ends Coning Tools Information Table

Comments

The brand on the tools ( VEXROTH ) reminds me of the tools from my Grandfather in the early 1970's and at this time not to much came from Asia and my GF was an professional Machinist. I had to work already with this tools and I'm happy, it is more expensive then other set, but you get what you paid for.

I was really impressed to discover there was a vertical style tool for the taps because at first all I saw was the horizontal style. That tool does not work in tight spaces so a crescent wrench was being used on those taps until I spotted the little baby vertical tool.

This is a good set of tap and dies upon inspection. I would rate them above average, but not amazing. The first thing I did with this set and what everybody should do, is inspect every tap and die to make sure there are no defects and that all sizes are present. All sizes were present, and I did not notice any defects visible to the eye.

Write A Comment